|

|

Post by farmboy on Mar 28, 2022 15:58:17 GMT -6

This kit has been around for a few years. It has a reputation as a difficult kit but I think I have enough info to build it and add a few details not included with the kit.  No guts no glory. Comments and observations welcome. |

|

|

|

Post by farmboy on Mar 29, 2022 7:51:10 GMT -6

a few words first. Ken Foran built Ivo's Showboat in brass from scratch in 1/8th scale. It's a superb and I believe reliable article to get ideas and answers from for this car and even includes a copy of a hand drawn diagram for the fuel delivery schematic from Bruce Dyda himself. The build article is on scalemotorcars.com. Credit where credit is due. The first thing I did was build all the engine blocks. The important part here is to keep a record of what engine has what oil pan and 'arm', and here's why. Two of the 4 pans had a cylinder added to them for additional oil. The instructions have you put those both on the right bank of engines. There should be one on each of the forward engines as shown below. A small change. I penciled in what engine was going where on the back of each one. Given my time back I think I would have left the oil pans alone and installed them per the instructions. The extra capacity tubes aren't really visible on the finished model and not many people would know one was in the wrong spot anyway. There's a lot of filing, cutting, and adjustment if you decide to install them 'correctly' and for most of us this is a busy enough kit as is without that added frustration. Just a heads up.  The 'arms' on the blocks are Revell's answer to helping keep the engines securely banked at the right angle during assembly. I'll use them for that purpose but be snipping them off when the engines are joined/installed. If you choose to relocate the oil pans the arms will need a small bit of modifying for a proper fit. Comments and observations welcome |

|

|

|

Post by rodsnracin on Mar 29, 2022 9:47:03 GMT -6

Good info, thanks! I've had this kit for many years but never started it. This might get me going!

|

|

|

|

Post by farmboy on Mar 29, 2022 12:29:37 GMT -6

Sounds like a plan man! This kit's been gathering dust for awhile also, plus the box recently survived a dachshund spite attack. It's time lol.

|

|

|

|

Post by rodsnracin on Mar 30, 2022 6:29:16 GMT -6

...the box recently survived a dachshund spite attack. It's time lol. Never had dog damage, but I had two glass shelves over a stairway that one of our cats knocked down. Shelves didn't break, but the models, well, let's just say "parts box filler"! |

|

|

|

Post by TooOld on Mar 31, 2022 4:20:26 GMT -6

Looking forward to this one !  |

|

|

|

Post by farmboy on Mar 31, 2022 6:41:29 GMT -6

I feel your pain Rodsnracin. Fortunately the resident cat is wayyyy too heavy to be shelf scalin' lol.

|

|

|

|

Post by farmboy on Mar 31, 2022 6:43:22 GMT -6

I'm going to give it a good try tooold. Hope it turns out ok.

|

|

|

|

Post by farmboy on Mar 31, 2022 17:48:24 GMT -6

4 engines painted. I did something I had read about a few years ago. The armor builder oversprayed various shades of the same green for a subtle effect. Why not? I sprayed the blocks a very bright red I had on hand and then generally but lightly oversprayed it with a darker shade of red. it's not terribly obvious but it's there. Guess that's the effect I was after. Neat. Each engine was pre-drilled with eight spark plug holes, and 8 individual header holes. I plan to do separate pipes, but, if that doesn't work out I'll still have plan B; the header mount from the kit. 64 holes total so far...65 if y ou count the one I accidentally put in the side of my fingerI  Comments and observations welcome. |

|

|

|

Post by farmboy on Apr 2, 2022 9:07:56 GMT -6

The paint has yet to fully cure. It's dry but has that almost-could-be-sticky feeling to it. It would probably take a partial finger print so I'm going to leave them alone for a couple of days. On to other things. The injection distribution setup as molded on this kit....even with molds over 50 years old is, in my humble opinion, pretty darn good.  A coat of black, a wash, some drybrushing, and I bet this entire piece would be a looker. I like to do my own -- for better or worse. If you're planning spark plug wiring AND fuel lines, I would recommend doing all/most of the fuel stuff first, plugs close to last as it's going to get pretty busy upstairs after a bit of additional detailing and you don't want plug wiring buried underneath stuff. I started with the distribution block  There are ten holes in this thing. Eight for fuel distribution, one for the side mount throttle lever, and one in the top for main fuel in. Three more to go. I went thru my wire stash and found a good likeness for the hoses. I'll cut the two injector banks apart, file between the injectors to smooth things over, add a base for this block to sit on along with a few other details and proceed from there. Comments and observations welcome. |

|

|

|

Post by flounder on Apr 2, 2022 13:58:14 GMT -6

I'm enjoying this one. I have this on my bucket list.

|

|

|

|

Post by farmboy on Apr 2, 2022 14:49:51 GMT -6

Hey flounder. It'll be an interesting build fer shur. Glad to have you along.

|

|

|

|

Post by farmboy on Apr 4, 2022 14:50:18 GMT -6

This is the dissected version of the kit supplied fuel assembly. As I mentioned earlier, this is a sharp piece with plenty of potential right out of the box but I simply prefer to do my own. The two injector rows will each have a small fuel inlet and fuel line attached. The middle piece goes in the small bag for homeless pieces in the parts box.  Here they are stuck to a strip of tape, painted, and ready to go. Like the red, it takes a day or two to fully cure before it can take any serious handling.  Comments and observations welcome. |

|

|

|

Post by farmboy on Apr 5, 2022 12:25:41 GMT -6

A change in technique was required to get the bones of the throttle mechanics together in a reasonable matter. I had planned to drill the appropriate size hole for the wire shaft to pass thru the barrels but that wasn't working out. Another tack was required. A razor saw and the back of an Xacto blade was the answer. I sawed shallow guide slots in the first and fourth injector openings, then lined up the saw to make a straight cut across all 4 openings. Using the back of the Xacto blade widened the slot to accept the width of the silver wire representing the throttle shafts.  The slots were cut deep enough for the wire so sit level with the top of the barrel rim, allowing me to stand an appropriate size ferrule (velocity stack) with no interference. A light respray is obviously required for these pieces. I was fortunate that I had painted them though as it allowed me to see how the cut was going.   I only added two ferrules in the above shots (they are just standing on there) so you can see the wire lying level with the rim edges for the middle two, and how neatly the two end tubes sit. The whole assembly is so small it looks like it has drilled holes....only straight. Comments and observations welcome. |

|

|

|

Post by farmboy on Apr 15, 2022 11:51:58 GMT -6

The blocks themselves have taken a bit of time and lots of fiddling to get right. First is the fore and aft spacing. Here is the end that connects to the timing cover of the engine in front of it  This next step isn't a necessary thing, but the molded frame mounts draw attention when the frame gets painted black and they get chromed. The engine mounts aren't accurate but at least they will attach at the relatively correct place on the frame. I would suggest you dry fit before making a commitment. They fit as is, but in my kit I found the engine mounts didn't match up with the frame mounts. The engine mounts are molded as part of the timing cover and are all wrong anyway but I'm ok with them. It's a wip, I may change my mind. I found first off that the two shafts on the engines have to be trimmed back. Basically the gear face ends up sitting flat against the timing cover of the other engine like below.  Despite this a little additional tweaking one way or another may be needed to look correct but I can live with that. The top holes in the timing covers are off center enough to put the cylinder heads out of line with the companion engine. A small bit reaming on one side of the hole brought things in to alignment. I used good old Testors' tube cement on the modded engine shafts and joined each engine upside down on a flat surface and left them to set up for a couple of hours. They were squared up by lining up against a 'fence' in this case a ruler, to keep them straight in both planes.   that's it for now. Comments and observations welcome. |

|

|

|

Post by farmboy on Apr 16, 2022 11:42:33 GMT -6

the 4 timing covers have two different part numbers. I didn't bother looking close enough and almost drilled a hole in the wrong part. Two of them have holes for each for the gear shafts to go in to. The other two are solid. See the photo below. The two solid pieces (part 12) will actually need a hole drilled in the lower plate cover. They're not often seen, but each bank of engines has a harmonic balancer on it. It's on the front engine on the right, on the rear engine on the left bank (...just walk away renee......). sorry. I'll simulate the balancers with 2 like buttons or punch out a couple of styrene circles, paint them black and mount them on the two timing covers  Below is the mockup of the 4 engines in the frame   I'm handling the engines enough that I've brushed a coat of Future on them to avoid any paint wearing on the high spots. It works. The 4 small engine braces between the heads will be left off till later as they seem like something that will just get in the way when installing fuel lines. I did test fit them and they friction fit nicely...and straight. One more thing I've omitted for now is the frame's bottom cross brace. What a pain that is. I'll alter/adjust/modify that piece to fit after the engines are installed. It won't allow the engines to sit level if you add it before then. Comments and observations welcome |

|

|

|

Post by farmboy on Apr 22, 2022 12:37:40 GMT -6

working on the injectors. It's taking a bit of time but they're getting there. The gold pieces are where the individual fuel lines will attach coming from the fuel distribution block. The holes on the ends of the pieces will be filled and painted over as the fuel lines enter from the sides on the real deal. Two injector banks per engine.  ...and here's the whole bunch for 4 engines for perspective  ..and a quick mock up  The injector banks are 1/4 done as there are still velocity stacks, fuel lines, and injector shaft/linkage to add. There's also a distribution block to tie the whole thing together that sits in the middle-ish of the valley cover. Hope I haven't bitten off more than I can chew! I gave in and added the two engine braces to each engine bank. The fuel pump assembly seems to me to be way oversize so there's some work to do there as they're needed for relationship. Comments and observations welcome. |

|

|

|

Post by farmboy on Apr 30, 2022 14:59:28 GMT -6

Here's where I'm at so far. The fuel distribution blocks mount in the middle of the valley cover. They more or less center left/right and are more fore/aft depending on which bank of engines you're referring to. The issue is, the block needs a good base to put up to my ham fisted plumbing of the fuel lines so I took a simplified approach of the real deal. The block is super glued to a same width piece of aluminum. This metal is bent a 90 degrees at the bottom corner of the block and trimmed to length. In my case, I made it just long enough to grab onto the injector bank as well as the valley cover. nice and secure.  The reason they mount more forward or back on the valley cover is to allow for the center linkage arm to attach to the throttle rod links. The most obvious place for this is between the wide gap(s) in the fuel injector velocity stacks.   Eight fuel lines down...24 more to go lol. Comments and observations welcome. |

|

|

|

Post by farmboy on May 8, 2022 16:04:41 GMT -6

32 individual fuel injector lines. Whew. Still have center holes to fill in the gold fittings but that's ok.  The fuel pumps, hard line plumbing, and injector linkages are on the agenda, but I'd like to get the assembly off the ground so may paint the frame and install axles. We'll see. Comments and observations welcome. |

|

|

|

Post by Paul B. Canney on May 8, 2022 17:10:23 GMT -6

that's some wild crazy detailing!!

|

|

|

|

Post by farmboy on May 8, 2022 18:04:42 GMT -6

Glad you're enjoying the build Paul. Thanx for the shout out.

|

|

|

|

Post by rodsnracin on May 9, 2022 5:57:39 GMT -6

Looking good, lots of neat stuff going on here, as usual! I have a hard enough time building two similar kits in a row, not sure I could slog thru a kit that needed four identical engines! I probably should sell my Showboat kit!

|

|

|

|

Post by farmboy on May 9, 2022 9:03:25 GMT -6

Well, I thought the same way before I began the build r&r, but I see the Ivo kit as different. Its one cohesive vehicle, the 4 engines aren't redundant, they're a part of the whole, not just building the same kit over and over. Remember the Nascar model craze? On the other hand I'd be embarrassed to tell you how many triplanes and Me/Bf109's I've put together. Go for it, and Thanx for the kind words.

|

|

|

|

Post by farmboy on May 27, 2022 14:25:53 GMT -6

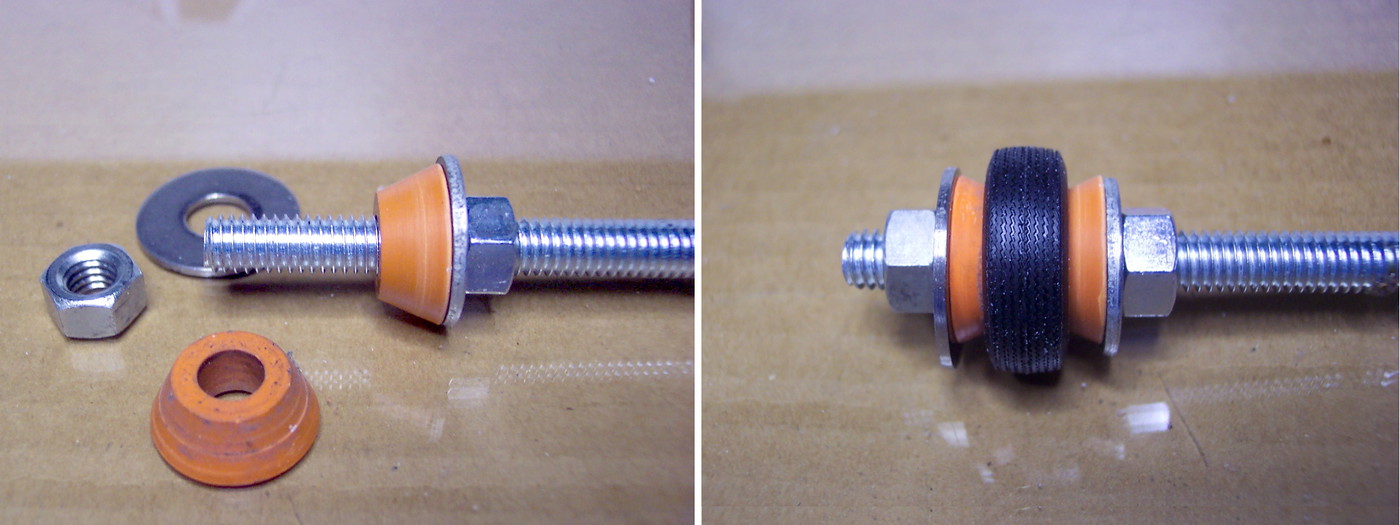

I have a few things done for upcoming parts of the kit. Made a few tees for fuel lines, drilled 8 holes in each of the 4 magnetos, made some fuel linkage levers, fine tuning the fuel pump assemblies...all part of engine detailing which is where I'm planning to head next. Took some time to take care of the tires by taking the shine off them. Here's a gadget I put together a few years ago from a cut off bolt, matching nuts and a couple of washers. It's pretty self explanatory. Does a good job.  Here's where I'm at more or less  I was going to wait till the engines were installed in the frame before detailing them, but now think they should be done before they get joined as a 4 engine clump. It'll be better to detail each 2-engine bank separately, making for easier handling, ensuring the velocity stacks are 90 degrees to the injector mounts plus wiring 'n stuff. comments and observations welcome. |

|

|

|

Post by TooOld on May 28, 2022 9:18:50 GMT -6

This is really coming together , those engines look great ! I've been using similar gadgets to sand/true my tires for years . A few years ago I found these cone shaped washers/seats at Ace Hardware in the faucet repair section , they automatically center the tires !   |

|

|

|

Post by farmboy on May 28, 2022 10:54:51 GMT -6

Now there's an improvement! Gotta get me a couple o' them! Thanx for the tip tooold!

|

|

|

|

Post by farmboy on May 31, 2022 14:48:48 GMT -6

These are a few of the 't''s I made for the fuel junctions made from 1/16" aluminum tubing

I just switched to my notepad so this was more an experiment to make sure it would work. More to come

|

|

|

|

Post by farmboy on May 31, 2022 19:27:22 GMT -6

These are the quite modified fuel pump assemblies  When I made adjustments to the two engine banks bringing the in line blocks closer together I didn't think about the fuel pumps. This resulted in having to adjust to the lost real estate. I thought the units were over scale to begin with and managed to shorten the length of the pump itself, filed a soft corner to better fit the engine it sits on and filed a notch in the base to sit a touch lower between them. It may not look like much but anyone with the kit might see the obvious differences. I also drilled a through hole for the base pin on the magneto to anchor directly in the block's mounting hole. Comments and observations welcome. |

|

|

|

Post by TooOld on Jun 2, 2022 7:06:28 GMT -6

Now there's an improvement! Gotta get me a couple o' them! Thanx for the tip tooold! I stumbled across them by accident but they sure do make it easier ! Those tee's and fuel pumps are soooo small ! How did you glue the aluminum tubing for the tee's ! |

|

|

|

Post by farmboy on Jun 2, 2022 11:51:09 GMT -6

Small is right, tooold. A magnifier/visor looks after what my eyes can't so that's half the battle. The hardest part is finding a way to hold small pieces so they don't go flying or get glued to your fingers. Tweezers and needle nose pliers are my best friends. As for the tee assemblies I prefer gel type c/a. It stays where you put it on small parts and gives you time to make quick adjustments if needed. File a round depression in the end of the 90 degree piece  I then put a small amount of gel glue on the end (it also helps any small gaps) and put them together. Voila  I obviously used larger plastic rod for the demo. Comments and observations welcome. |

|